Sugar Valley Hidrolife SAL 16

- Salt electrolysis equipment.

- Production: 16 g/h.

- Water salinity: 3 grams of salt per litre.

- Removable display.

- Optional automatic controls: pH, redox, free chlorine, conductivity, temperature.

- Self-cleaning cell with titanium plates.

- New model with touch screen

- Manufacturer: Sugar Valley.

- Code: SAL16.

Bought together Usually

Actual product

Actual product

Technical characteristics

What is salt electrolysis?

- A new concept to improve water quality.

- Generates chlorine from the common salt dissolved in the pool water.

- It avoids the handling of chemicals and simplifies maintenance.

- Ensures a healthier and more pleasant bathing experience.

Advantages

- Clearly healthier.

- Economical and easy to install in any type of pool.

- Completely eliminates chlorine consumption.

- Can be operated with seawater.

- Prevents itching and irritation of eyes and skin.

- Protects tissues.

- Promotes tanning.

- Minimal maintenance.

Features Hidrolife SAL

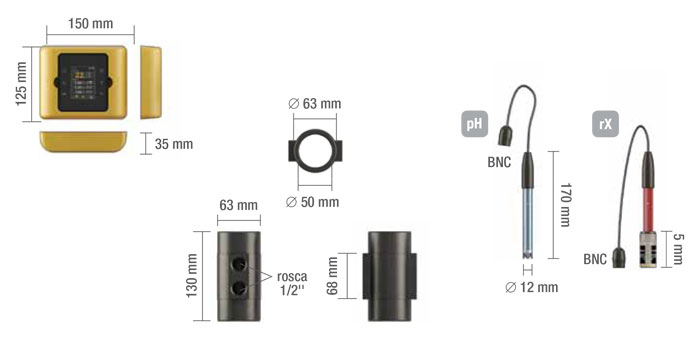

- Removable display.

- Access menus with security passwords.

- Safety: lack of flow / lack of salt / cover detection.

- Direct production in grCl/h.

- Optional automatic controls for pH (+/-), redox, Cl, conductivity and temperature.

- Safety: dosing time exceeded.

- Setpoints, waiting times and dosing configurable with patterns or at a single point.

- Automatic or manual operation.

- Compatible with VISTAPOOL remote control by cable or via WiFi.

Private swimming pools

Clearly more rewarding.

For greater convenience, all models have a removable touch screen, with a wired or Wi-Fi connection for monitoring water parameters without leaving the house.

SUGAR VALLEY BRANDS, based on the salt electrolysis principle of operation: HIDROLIFE, BIONET

Principle of operation

SALT ELECTROLYSIS

The traditional form of water treatment in swimming pools consists, fundamentally, of adding chlorine in any of its commercially available forms.

SALT ELECTROLYSIS SYSTEMS provide a new concept for the treatment of your pool, improving the quality of the water, avoiding the handling of chemical products and simplifying maintenance tasks as they generate chlorine from the common salt dissolved in the water. The salt necessary for its operation must be added to the pool in a concentration of 4-6 kg/m3 (5-6 times less than sea water). The salt is added to the water and chlorine (Cl2) is produced at the anode of the electrolytic cell by the following electrolysis reaction:

2NaCl+2H2O=2NaOH+H2+Cl2

(salt+water=soda+hydrogen+chlorine)

This chlorine dissolves in water to form hypochlorous acid:

Cl2+H2O=HOCl+HCl

(chlorine+water=hypochlorous acid+hydrochloric acid)

The hypochlorous acid oxidises the bacteria. As can also be seen, another product is generated, active oxygen (O2), which adds extra disinfectant power to the process, thus sterilising the water:

2HOCl=2HCl+O2

(hypochlorous acid=hydrochloric acid+oxygen)

Once the water has been disinfected, the hydrochloric acid reacts with the caustic soda in a neutralisation reaction, giving salt and water again. Hydrogen and oxygen react to form water:

NaOH+HCl=NaCl+H2O

(soda + hydrochloric acid = salt + water)

It is a closed process in which no product is lost.Salt should only be added once when the pool is filled. Only small periodic replenishments should be made due to water losses during filter rinsing.

The chlorine generated destroys the organic matter and pathogens present in the water and is transformed back into sodium chloride (common salt).

The products decompose, act and regenerate again. This explains why the salt concentration remains constant.

Data Sheet

- gr/hour CL

- 15-19 g/hour

- Recommended pool size

- 20-50 m3

- With pH control

- No

Might Also like

- On sale!

- Top Sales